Juki JM-100 Insertion machine

Rated 5.00 out of 5 based on 1 customer rating

(1 customer review)

JUKI JM-100 pcb insertion machine is a high-speed, multi-functional surface mount technology (SMT) placement machine designed for use in electronics manufacturing. It combines speed, precision, and versatility, making it ideal for assembling various electronic components on printed circuit boards (PCBs).

Category: Insertion machine

Description

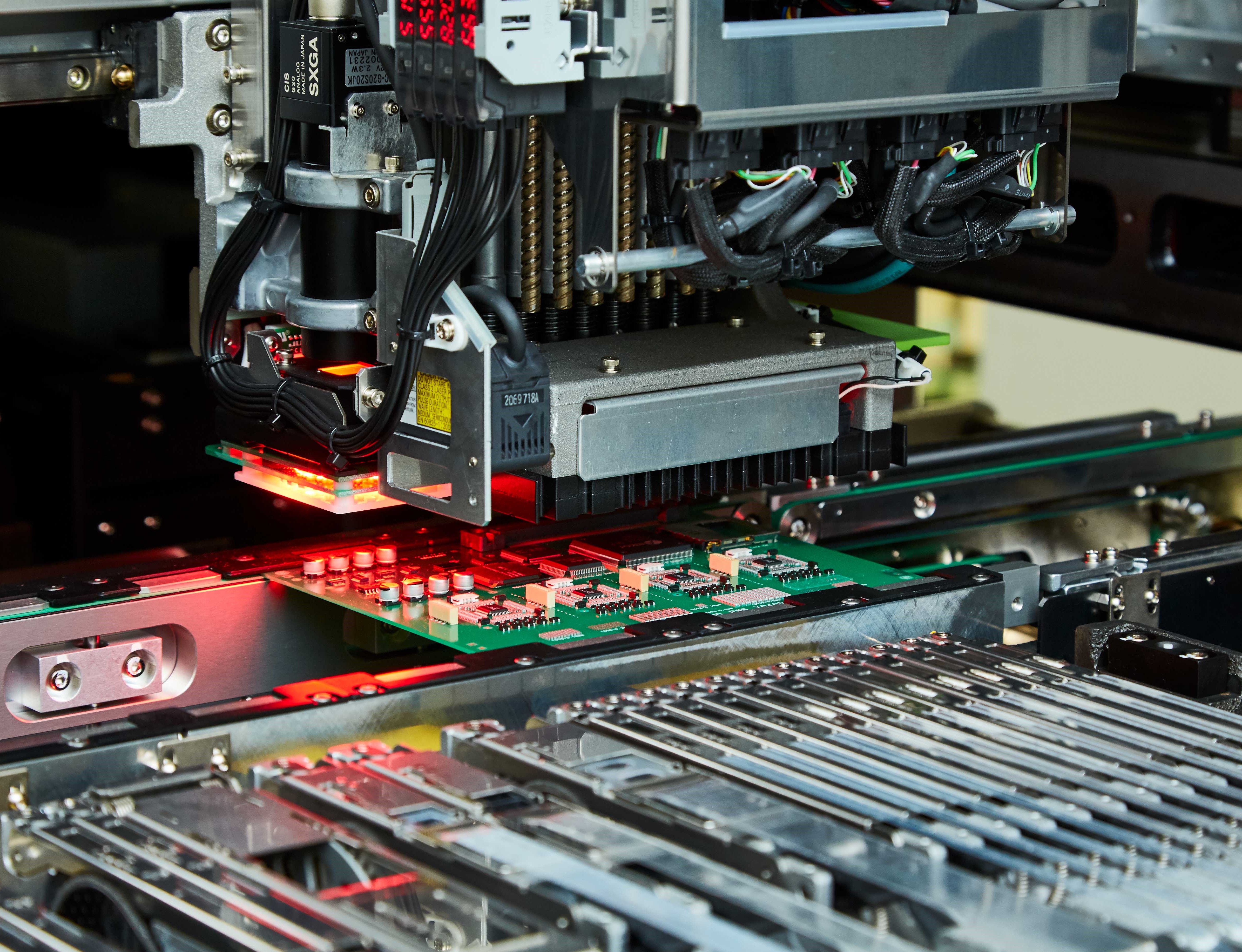

JUKI JM-100 insertion machine

Juki provides a high-tech pcb pin insertion machine, which is Juki’s most advanced pin inserter JM 100 which supports both radial insertion and axial insertion machine technology.

juki jm-100 pcb insertion machine

| Juki JM-100 Insertion machine | ||||

|---|---|---|---|---|

| Standard specification (Lsize PWB) |

Clinch specification (Lsize PWB) |

|||

| With using Clinch unit | Without using Clinch unit | |||

| Board Size | 1 time clamping | 50㎜×50㎜~410㎜×360㎜ | 80㎜×100㎜~410㎜×360㎜ | 80㎜×50㎜~410㎜×360㎜ |

| 2 times clamping | 50㎜×50㎜~800㎜×360㎜ | 80㎜×100㎜~800㎜×360㎜ | 80㎜×100㎜~800㎜×360㎜ | |

| PCB Weight | max.4kg | |||

| Component Height | max.30㎜ | |||

| Component Size | Laser recognition | 0603~□50mm | ||

| Vision recognition | □3mm~□50mm | |||

| Insertion Speed (Insertion components) |

Vacuum | 0.6 sec/part*1*3*4 | ||

| grip | 0.8 sec/part*2*3*4 | |||

| Placement Accuracy (SMT) |

Laser recognition | ±0.05mm(3σ) | ||

| Vision recognition | ±0.04mm | |||

Specifications of JUKI JM-100 Insertion machine for DIP

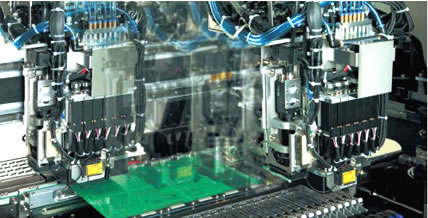

Takumi head

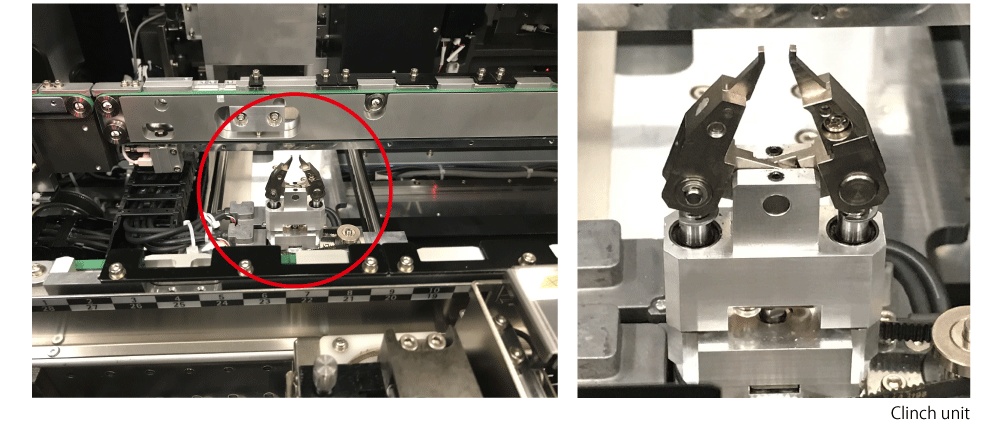

Active clinching

Juki JM-100 PCB insertion machine has a new active clinch unit supports bend in, bend out, and N bend to prevent components from lifting during reflow and make handling before reflow easier.

laser centering

A high-resolution laser is mounted on the head to center components in all directions, including angles. Centering is done on the fly, allowing high-speed placement of components from small chips to SOPs.

Adaptable centering

Centering accommodates component variations

Laser centering measures the components on the side. It is not affected by variations of component color or width/length so, unlike vision centering, there is no need to edit component data for different component vendors.

The component check function improves placement reliability

Since the laser is mounted on the head, it can be used to monitor the presence of components the entire time from pick to placement. This is difficult to accomplish with vacuum detection only. The placement reliability is also improved because the release of the component is confirmed after placement.

Key Features:

- High Placement Speed:

- The JM100 offers a competitive placement speed, allowing for efficient production in high-volume manufacturing environments.

- Wide Component Range:

- It supports a broad spectrum of components, from ultra-small chips (0201 metric) to larger components like connectors and odd-shaped parts.

- Advanced Vision System:

- Equipped with a sophisticated vision system for precise component recognition and placement, ensuring high accuracy.

- Flexible PCB Handling:

- Capable of accommodating various PCB sizes, the machine supports flexible production requirements.

- Modular Design:

- The JM100 can be integrated into existing production lines and scaled according to production needs.

- Ease of Use:

- User-friendly software and interface streamline programming, changeovers, and maintenance.

- Reliability:

- JUKI is known for building durable machines with a long operational life and low maintenance requirements.

Applications:

- Consumer Electronics: Smartphones, tablets, and wearables.

- Automotive Electronics: Sensors, ECUs, and infotainment systems.

- Industrial Electronics: Control systems and IoT devices.

- LED Assembly: Placement of LED components for displays and lighting solutions.

The Juki insertion machine JM100 is a versatile choice for businesses looking to enhance their SMT assembly capabilities, particularly in high-mix, medium-volume production environments.

JM 20 is the basic starting level inserter.

Reviews (1)

1 review for Juki JM-100 Insertion machine

Add a review Cancel reply

Shipping & Delivery

Pick and Place

Pick and Place

Rework Station

Rework Station

Solder Paste Printers

Solder Paste Printers

Reflow Ovens

Reflow Ovens

Reel Storage System

Reel Storage System

AOI & SPI INSPECTION

AOI & SPI INSPECTION

Soldering Machines

Soldering Machines

Insertion Machine

Insertion Machine

X-ray inspection

X-ray inspection

PCB Handeling

PCB Handeling

Depaneling Machine

Depaneling Machine

asad.kamran4321@gmail.com –

UKI JM-100 pcb insertion machine is a high-speed, multi-functional surface mount technology (SMT) placement machine designed for use in electronics manufacturing. It combines speed, precision, and versatility, making it ideal for assembling various electronic components on printed circuit boards (PCBs).