SMT MACHINE

GET YOUR

SMT Equipment

PICK AND PLACE MACHINE, SOLDER PASTE PRINTER , REFLOW OVEN, PCB HANDLING AND MANY MORE..

FEATURED SMT LINE EQUIPMENT

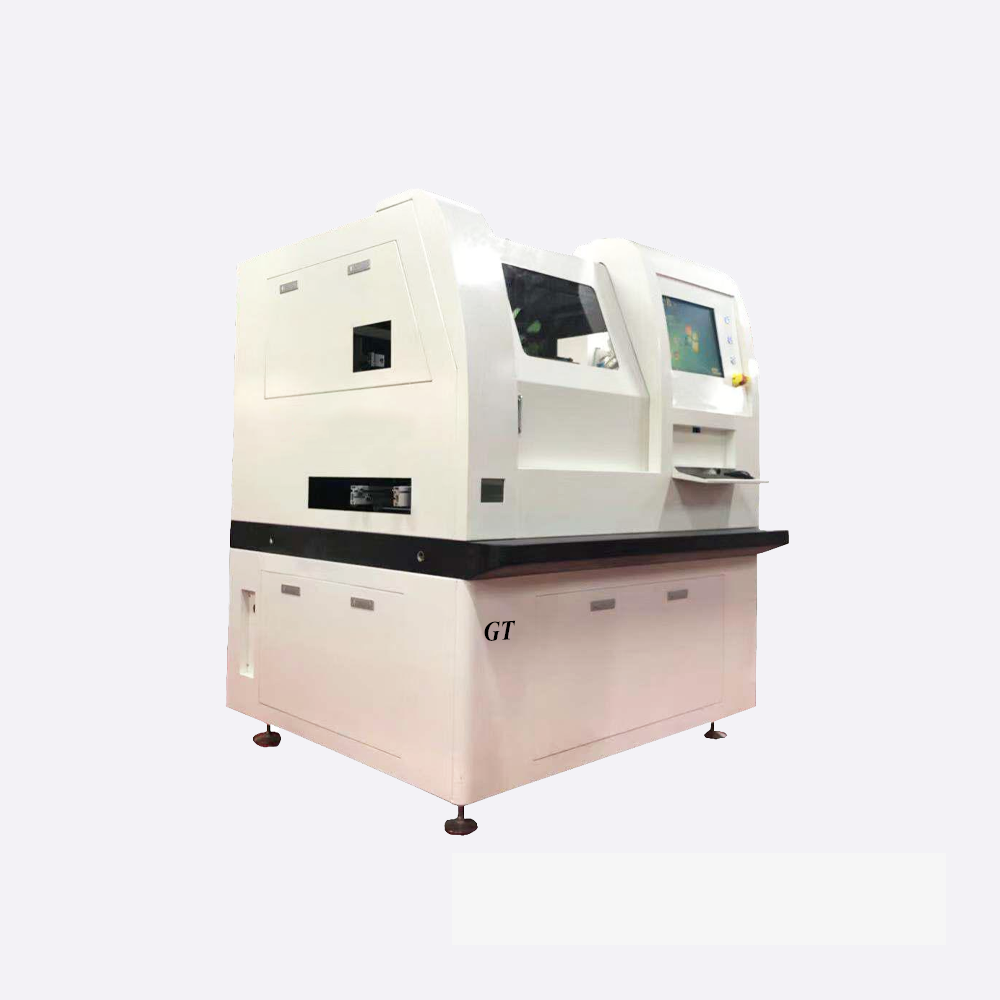

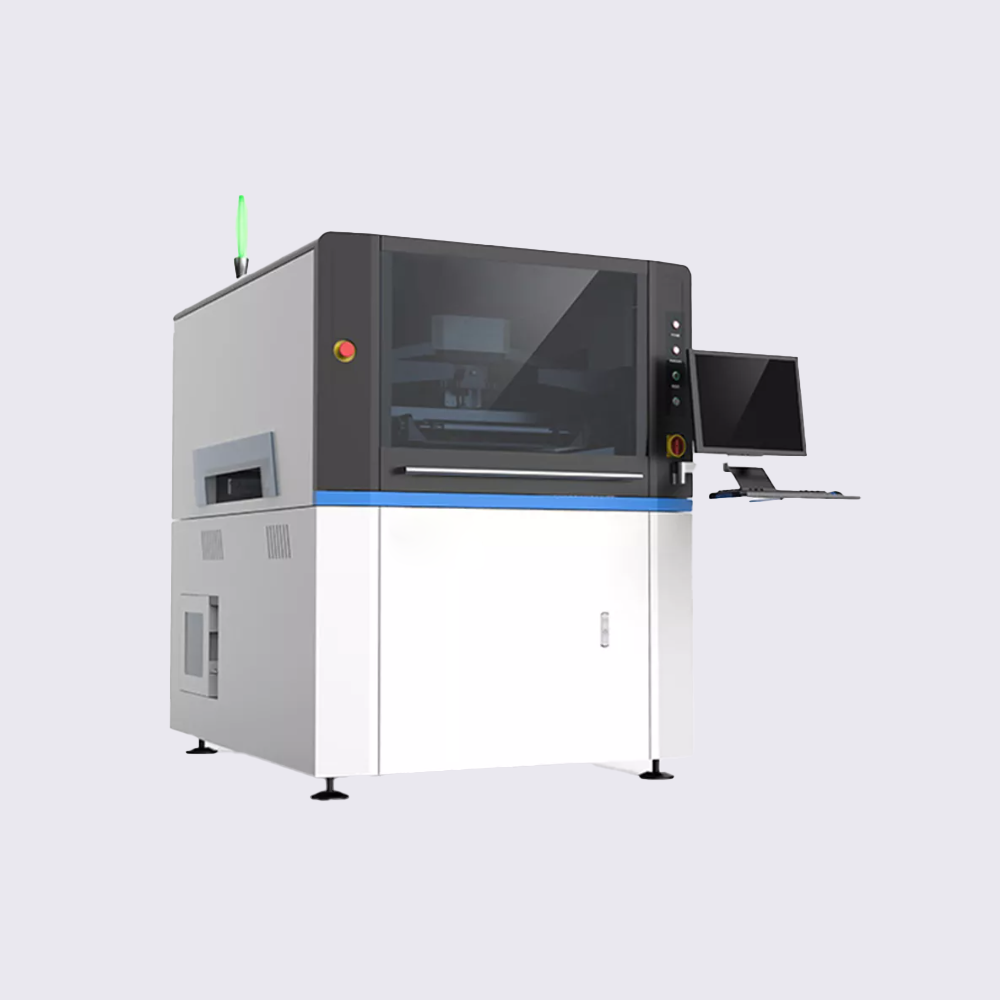

Solder Paste Printer

GT Solder Paste Printer

REFLOW OVENS

Maxflow Reflow Oven series

AOI & SPI Inspection

Inpex 3d and 2D AOI Machine

Xray machine

Xmark xray machine

PCB Handling

Loader and Unloader

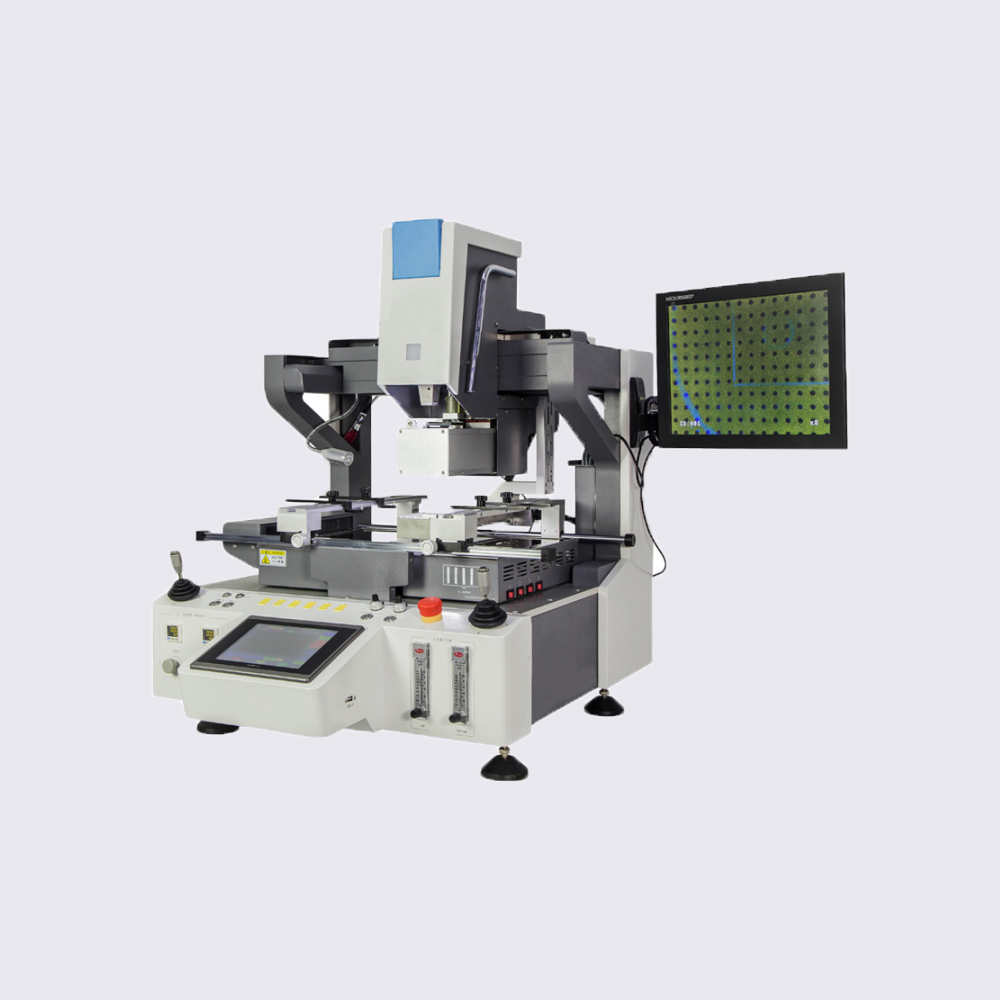

BGA Rework station

Rework Station

DIP Insertion

Hole-Through SMT

Keep in Touch!

Guangdong

Shenzhen– 518104

(86)18587477426

sales@gtsmt.com