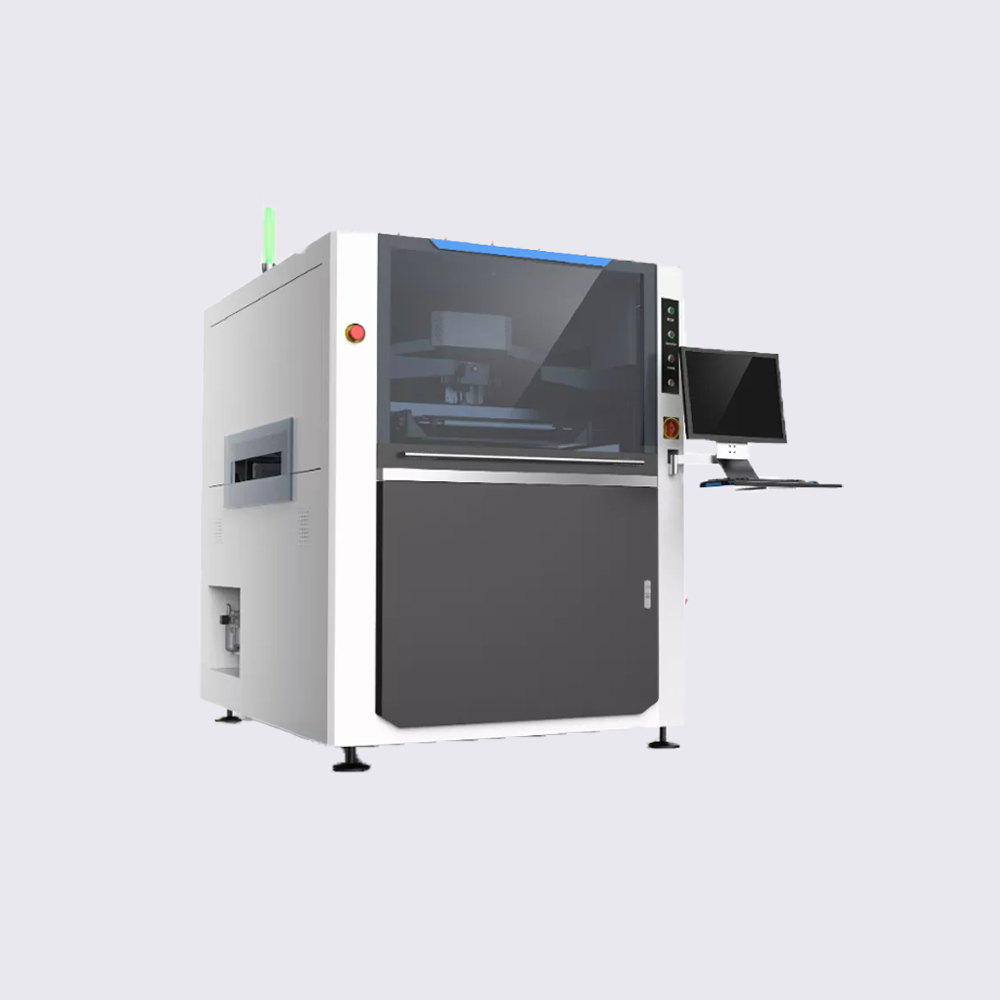

GT Solder Paste Printer P6

1. Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn.

2. Expertise: learn imported reflow oven advanced design concepts, and the machine core components using imported top brands.

3. Hedging: Import hardware configuration, the low failure rate in production, more than a decade of service life

Frame and Structure: The printer typically consists of a sturdy frame that holds the various components and mechanisms. It provides stability and precision during the printing process.

Printing Bed: The printing bed is a flat surface where the PCB is placed for solder paste application. It usually has adjustable fixtures or clamps to securely hold the PCB in place.

Stencil Alignment System: A solder paste stencil is used to define the areas where solder paste needs to be applied on the PCB. The printer incorporates an alignment system that precisely aligns the stencil with the PCB, ensuring accurate paste deposition.

Squeegee Mechanism: The printer employs a squeegee mechanism to deposit the solder paste onto the PCB. Typically, a metal or rubber blade, known as the squeegee, is used to push the solder paste through the stencil openings and onto the PCB’s pads.

Vision System: Many solder paste printers are equipped with a vision system that uses cameras and software to inspect the alignment of the stencil and PCB, ensuring proper registration. It can also detect defects such as missing or excessive solder paste.

Programmable Control: Solder paste printers are controlled by software that allows for precise control of various parameters, such as squeegee speed, pressure, and separation distance. The software may also provide features like automatic fiducial recognition and compensation for uneven PCB surfaces.

Cleaning Mechanisms: After the solder paste is applied, the printer may have cleaning features to remove excess paste from the stencil and squeegee. This helps prevent contamination and ensures consistent printing quality.

User Interface: Solder paste printers typically have a user-friendly interface that allows operators to set up printing parameters, monitor the process, and make adjustments as necessary.

| Model | P6 | |||

| Frame Size (mm) | 650*400 ~ 850*850 | |||

| PCB Size (mm) | 80*50 ~ 650*610 | |||

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right | |||

| Support System | Magnetic Pin/Up-down table adjusted/support block | |||

| Clamping System | Side clamping, vacuum nozzle, Automation retractable Z pressure | |||

| Printer Head | Two independent motorized print head | |||

| Squeegee Type | Stainless steel (standard), plastic | |||

| Cleaning System | Dry, Wet, Vacuum | |||

| Inspection | 2D Inspection (Standard) | |||

| Power Supply | AC:220±10%,50/60HZ,3Kw | |||

| Control Method | PC Control | |||

| Dimension (mm) | 1330*1530*1500 | |||