- The transportation system adopts section floating structure, effectively prevent guide rail deformation, new titanium alloy double hook finger,non-stick tin, direct linkage buffering, aluminum guide rail, more smooth.

- Spray unit integrated module design, through the fast connector connected with the machine; adopts new precision nozzle, which can achievehigh efficiency, uniform atomization coating effect and meet the process requirements of water flux.

- The preheating system adopts micro-hot air + infrared heating tube, three-section preheating temperature zone, drawer type modular design,flexible selection of mixed preheating mode, uniform and stable temperature.

- Forced air cooling system (Water chiller is optional).

- The solder pot system adopts special material for pot, and anti-corrosion treatment for inner surface. (New nozzle fixed mode, easy to remove and assembly; the solder pot temperature control precision is ±2℃; solder pot electric/manual lifting in and out, easy to operate.

- Windows 7 operating system, Chinese/English intelligent software, with parameter setting, saving, reuse, remote monitoring functions. Process profile/data automatic storage function, temperature profile test function.

Machine Optionals

Integrated spray fluxer unit(selective spray device is optional)

Drawer type and modular structure preheating zone

Cast iron soldering pot with special anti-corrosion coating

Manual width adjustment with digital display

Solder pot electric/manual lifting in and out

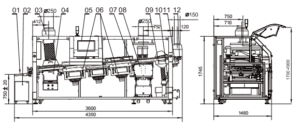

Machine diagram

Item | W-450 |

Dimension: L*W*H(mm) | 4350*1580*1750 |

Weight | Approx.1950kg |

Power Supply | 3PH 380V 50HZ |

Start up Power | 32KW |

Normal Running Power | Approx.8.5KW |

Control System | PC+PLC |

Spraying movement | Step motor |

Spraying Pressure | 0.2Mpa~0.4Mpa |

Flux Flow Control | Option |

Auto Flux Filling | Standard |

Exhausting | Top exhaust+Side exhaust |

Exhausting Pipe Diameter(mm) | Φ250 |

Exhaust Capacity | 30m³/min |

Preheating Mode | (Hot air convection/IR) |

Temperature Control Mode | PID |

Preheating Zone Quantity | 3 |

Preheating Zone Length(mm) | 1800 |

Preheating Temperature Range | (Room temperature)~200℃ |

Warm-up Time(min) | Approx.12min(setting: 150℃) |

Preheating Blower Motor | 250W 3PH 220 VAC |

Width(mm) | 50~450 |

PCB Conveying Direction | L→R( Option:R→L) |

Conveying Speed(mm/min) | 500~1800 |

Conveying Height(mm) | 750±20 |

Available Component Height(mm) | (Top)120(Option:250)(Bottom)15 |

Conveying Speed Control Mode | (Closed loop stepless speed regulation by inverter) |

Finger | ( Spring Pressing Finger);(D-40 Type Finger); (Double-hook Finger);( Heavy type double hook finger)(Options) |

Conveying Angle | 4~7° |

Solder Pot Type | (Mechanical) |

Solder Pot Material | (Casting Iron) |

Wave Height Adjustment | ( Inverter):( Digital Control by PC) |

Cooling type | ( Air Cooling) Option:( Water cooling) |

Solder Pot Heating Power | 13.5KW |

Max Solder Pot Temperature | 300℃ |

Solder Pot Capacity | Approx.550kg |

Wave Driving Power | 180W*2 3PH 220 VAC |

Solder Pot Warm-up Time | Approx.150min(setting: 250℃) |

Temperature Control Mode | PID |

Finger Cleaning System | (Brush) |