The Vital Role of AOI Machines in SMT Production: Why GTSMT Delivers Superior Inspection Solutions

Introduction

In modern Surface Mount Technology (SMT) assembly lines, Automated Optical Inspection (AOI) has become an indispensable quality control checkpoint. AOI machines play a critical role in detecting defects early, ensuring product reliability, and reducing costly rework. Among the top-tier AOI equipment providers, GTSMT stands out with its high-speed, high-precision inspection systems designed for maximum efficiency and accuracy in SMT manufacturing.

Why AOI Machines Are Essential in SMT Production

1. Early Defect Detection for Higher Yields

AOI systems inspect PCBs after solder paste printing, component placement, and reflow soldering to identify issues such as:

- Missing/misaligned components

- Solder bridging or insufficient solder

- Polarity errors and tombstoning

- Scratches or foreign material contamination

By catching defects early, manufacturers avoid costly failures in later production stages or field returns.

2. High-Speed Inspection Without Slowing Production

Modern SMT lines run at extremely high speeds. GTSMT AOI machines utilize advanced imaging algorithms and high-resolution cameras to inspect PCBs in real-time without bottlenecking throughput.

3. Data-Driven Process Improvement

AOI systems generate detailed defect reports, enabling manufacturers to:

- Identify recurring issues (e.g., solder paste problems, pick-and-place misalignment).

- Optimize machine settings for better process control.

- Meet traceability requirements for industries like automotive and medical electronics.

4. Reduced Reliance on Manual Inspection

Manual visual inspection is slow, inconsistent, and prone to human error. GTSMT AOI machines provide objective, repeatable, and fast defect detection, improving overall quality control.

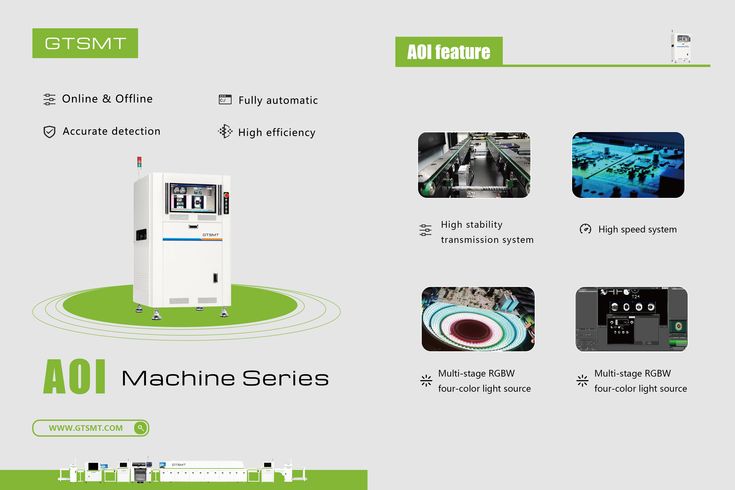

Key Features of GTSMT AOI Machines

✔ Ultra-High-Resolution Imaging

- Multi-angle cameras & advanced lighting to detect even micro-defects.

- 3D inspection capability for solder joint height and shape analysis.

✔ AI-Powered Defect Recognition

- Deep learning algorithms to minimize false calls and improve accuracy.

- Self-learning capabilities that adapt to new PCB designs over time.

✔ Fast & Flexible Inspection

- High-speed scanning to keep up with SMT line speeds.

- Easy programming for different PCB layouts and component types.

✔ Seamless SMT Line Integration

- Compatible with SPI, pick-and-place, and reflow systems for closed-loop feedback.

- Network connectivity (Industry 4.0 ready) for real-time data sharing with MES/ERP systems.

Why Choose GTSMT AOI Machines?

- Unmatched Accuracy – Minimizes false passes/failures with AI-enhanced inspection.

- Blazing-Fast Speed – Inspects complex boards without slowing production.

- User-Friendly Software – Intuitive interface for quick setup and defect analysis.

- Low Maintenance & High Reliability – Built for 24/7 operation in demanding factory environments.

Conclusion

In today’s high-speed SMT manufacturing, AOI inspection is no longer optional—it’s a necessity. GTSMT’s advanced AOI machines provide fast, reliable, and intelligent defect detection, ensuring higher first-pass yields and lower production costs.

For manufacturers seeking to enhance quality control and efficiency, GTSMT AOI systems deliver cutting-edge performance with industry-leading precision.

Upgrade your SMT line with GTSMT AOI – where smart inspection meets flawless production!

Need help selecting the right AOI model for your application? Contact us for a customized solution!

Pick and Place

Pick and Place

Rework Station

Rework Station

Solder Paste Printers

Solder Paste Printers

Reflow Ovens

Reflow Ovens

Reel Storage System

Reel Storage System

AOI & SPI INSPECTION

AOI & SPI INSPECTION

Soldering Machines

Soldering Machines

Insertion Machine

Insertion Machine

X-ray inspection

X-ray inspection

PCB Handeling

PCB Handeling

Depaneling Machine

Depaneling Machine